亮点

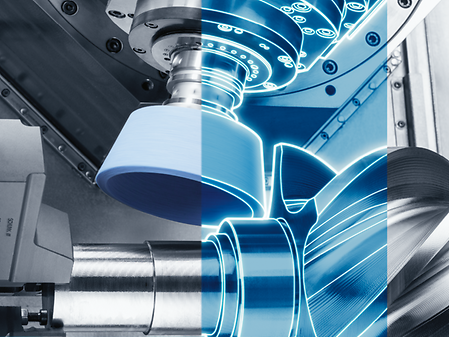

Largest DMF working area with 6 m travel and 12.000 kg table load

- 4-axis machining with B-axis for workpieces up to 7,200 x 1,100 x 1,100 mm and 12,000 kg

- 5-axis machining with integrated NC table (optional) for workpieces up to Ø 1,400 x 1,050 mm and 2,000 kg

- Partition wall (optional) for 2 independent working areas 3,600 x 1,100 x 1,100 mm

Highest stiffness and damping

- 3 linear guides in the X-axis and a one-piece machine bed made of gray cast iron

- High accuracy and cutting performance in total working area

- Best surface quality with X-Linear drive, Y/Z with direct cooled & grinded ballscrews

Large spindle variety & process integration

- speedMASTER (ISO 40) up to 24,000 rpm or 200 Nm

- powerMASTER (ISO 50) spindles up to 16,000 rpm or 430 Nm

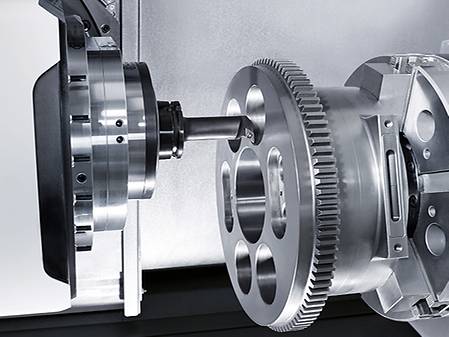

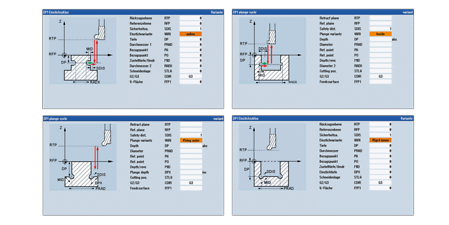

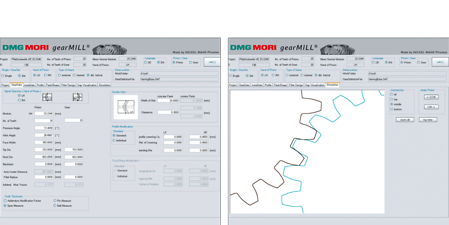

- Process integration: Mill-Turn, gearSKIVING, grinding, fine boring, deep hole drilling

Highest productivity on your shopfloor

- Collision-free tool change outside the working area with a maximum capacity of 300 tools

- Dynamic 3-/4- or 5-axis machining with high feed rates in the linear and rotary axes

- High dynamics in the basic version with 42 m/min and maximum dynamics in the linear version with up to 80 m/min

- Automation interfaces with and without partition walls – also for alternating loading (pendular machining mode),, e.g. Robot or AMR for high machine utilization

- Wide range of working table options—perfect for all requirements

应用举例

自动化系统

采用VERTICO设计的标准自动化和定制化解决方案

自动化是数字化生产的关键要素。每一台DMG MORI机床都可通过标准自动化或定制自动化解决方案进行升级,确保灵活的制造系统:

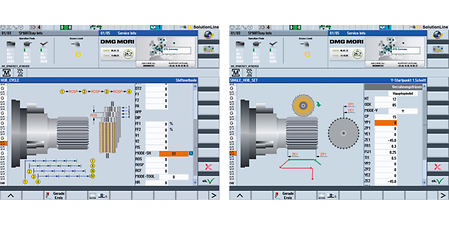

数控系统和软件

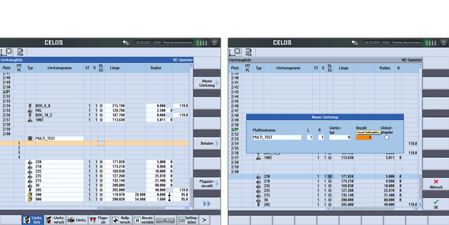

CELOS

将DMG MORI机床和车间数字化:

- CELOS机床:基于APP应用程序的用户界面,提供有关生产的全面信息

CELOS生产:27款CELOS APP应用程序,有效准备和处理任务单

- 数字化工厂:连续的数字化工作流程,从生产计划到生产和服务