亮点

进一步开发经验证的 DMU eVo 概念产品

- 刚度和精度提高 28%

- 作业区空间比前一代机床扩大 40% 以上

- 单体式混合机床床身由矿物铸件制成,机床夹具加宽 25%,Y 轴有 3 个导轨

精确

- 4 微米双球杆仪测试 (DBB)

- 通过 45 毫米线性导轨和优化的铸造设计,Z 轴的刚度提高 80%

- 采用完全温控解耦机床框架实现较高长期热稳定性

高产性

- speedMASTER 主轴转速高达 30,000 rpm 或 200 Nm,标准为 20,000 rpm 和 130 Nm

- 基本型高动态性能(50 米/分钟),线性型动态性能最高达 80 米/分钟

- 由于采用全新、联动开启刀具更换装置挡板,最短排屑机到排屑机时间仅为 4.5 秒

通用

- 最多可容纳 300 把刀具,装夹与加工同时进行

- 由于采用整体不锈钢盖板,排屑机的开口增大 60%,可实现最优的切屑流动

- 为自动化做好准备——灵活的准备工作使后续自动化过程更加容易

- 通用自动化工作台,Z 向安装高度增加 35 毫米

- 无论是 30、60 或是 120 把刀具,安装区仅为 9 平方米

应用举例

自动化系统

采用VERTICO设计的标准自动化和定制化解决方案

自动化是数字化生产的关键要素。每一台DMG MORI机床都可通过标准自动化或定制自动化解决方案进行升级,确保灵活的制造系统:

来自DMG MORI的通用型托盘搬运自动化

- 直接通过机床控制系统进行控制

- 从24个ø148的圆形托盘到4个500×500毫米的托盘,有多种可供选择的配置

- 标配工件重量为150kg(可选配最大重量至250kg)

- 可对订单进行优先排序

- 标配EROWA夹持系统,可选配SCHUNK夹持系统

- 夹持重复精度高(EROWA UPC-P卡盘的重复精度<0.002mm)

- 最优的机床和自动化的可及性

PH Cell 500 - 多达 32 个托盘的模块化托盘处理系统

- 仅 10.7 平方米的模块化自动化理念

- 使用铸铁锥形托盘

- 传送重量达 500 千克(包括托盘)

- 最大工件尺寸 500x500x750 毫米

- 400x400 和 500x500 毫米托板

- 模块化设计理念,符合人体工程学,方便使用

CN: PH Cell Twin - 适用于2台机器和多达30个托盘的模块化托盘处理

- 一个托盘搬运装置用于2台机床

- 由于每层都有双排托盘库,在12.9平方米的面积上可存放30个托盘

- 工件最大尺寸可达500mm x 500mm x 500mm

- 搬运重量可达300公斤(包括托盘)

- 系统可扩展,能方便接入第二台机床

- 价格诱人的DMG MORI VERTICO自动化设计系统

PH cell 300 - 最多可容纳40个托盘的模块化托盘搬运系统

- 模块化的自动化概念,在10.7平方米的面积上有多达40个存储位置

- 在一个系统中搬运不同尺寸的托盘

- 转移重量高达300公斤(工件包括托盘)

- 独立的装卸站,符合人体工程学,可同时装载和卸载托盘

- 直接通过机器控制面板对自动化进行控制,操作方便且简单

Robo2Go 铣削 - 灵活的工件搬运,适用于中小批量

- 一个应用程序适用于所有Robo2Go变体,工件示教对话式编程可在15分钟内完成

- 坚固的结构满足所有要求,负载能力可选择25或35公斤

- 搬运工件的尺寸为20-200mm

- 保持对机器的完全可访问性

- 对准和车削站,用于自动化的6面完整加工

- 通过CELOS APP集成到机床控制操作中:不需要改变你的NC程序!

- 对话引导式软件使其具有直观的可用性

- 通过拖放预定义的程序模块来创建工艺:不需要机器人编程知识

- 设置一个新工件< 5分钟

- 结构坚固,可满足所有要求。机器人有效载荷可选择25或35公斤

- 可搬运尺寸为20 - 200 mm的部件

高度灵活、协作性强的自动化系统,可处理重达 10 公斤的工件

- 可自由移动的工件处理装置,包括机器人和手推车上的存储区

- 工件重达 10 千克,或 5 × 2 千克(带双手爪)

- 基础设施不变

- 无需安全围栏

- 占地面积 600 × 900 毫米

- 协作机器人,设置时间小于 5 分钟*

- 无需机器人知识的直接示教

- 通过以太网轻松连接

- 可选择两种类型的料库

- 最多可存储 64 个工件

- 吹气清洁装置

- 二次定位台

*当选择了可选的标签位置校正功能或机器/工件设置已完成时。

可同时处理工件和托盘搬运的柔性自动化系统

- 载荷:最大210公斤(MATRIS WPH 210)

- 可处理工件(长 x 宽 x 高)的最大尺寸为340 x 250 x 250毫米(MATRIS WPH 210)

- 可处理重达150公斤的托盘(MATRIS WPH 210)

- 可使用机械手更换装置

(工件、机械手、托盘、货架)进行通用处理 - 抽屉式储物柜,可实现最大容量

- 可移动的架子,可放置不同尺寸的装置

- 导引式HMI控制器

- 快速安装和维护

灵活的模块化机器人系统,适用的机床数≥1台机数

- 模块化概念设计的标准化辅机设备,如清洗、测量或打标

- 得益于模块化和标准化的辅机设备和机器人程序,安装时间缩短80%

- 灵活适应系统变化,包括安装后的变化

- 通过MATRIS控制系统简单易行,无需编程

- 日产50至200件,灵活生产的理想选择

- 占地少的托盘运送系统,多达40盘位

- 400 × 400 mm的托盘规格

- 运送重量达150 kg(工件和托盘)

- 含辅助操作,例如去毛刺或打标

- 可配CMX 50 U, CMX 70 U, DMU 50, DMU 65 monoBLOCK, CMX 600 V, CMX 800 V, CMX 1100 V

自由式布局设计赋予托盘自动转运最大的灵活性

- 模块化方案,具有灵活的布局设计

- 无人驾驶运输系统,无需导轨或轨道

- 协同作业:人机一体化

- 自然导航

- 托盘尺寸从 500 x 500 mm 到 1,600 x 1,250 mm

- 工件最大 5,000 kg,φ 1,600 mm

随时访问

- 随时获得最佳的工作空间可视性

- 仍可人工或起重机装载

- 协同作业系统,人机一体化

模块化方案,自由布局设计

- 自动化系统无需安全外壳

- 各模块可自由定位

- 可随后集成到现有生产中

轻松扩展自动化系统

- 可附加机架模块,以增加存储位置的数量

- 可在系统中集成其他 AMR

- 机床配有自动化接口,后续可快速集成。

空间要求极低

- 自由的托盘搬运系统,无需在大厅地板上进行固定安装

- AMR 通道仍可步行和通行

- 激光扫描仪确保在行驶方向上的人身安全

- 可全向移动,空间需求最小(车削半径 0m)

- 灵活的自动化理念,使用一个系统实现不同机床类型的自动化

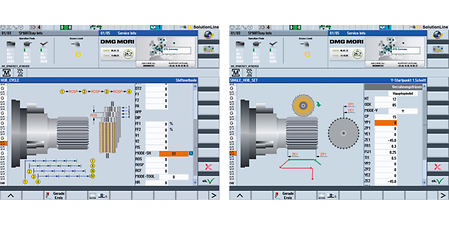

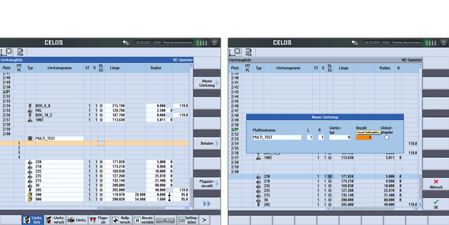

数控系统和软件

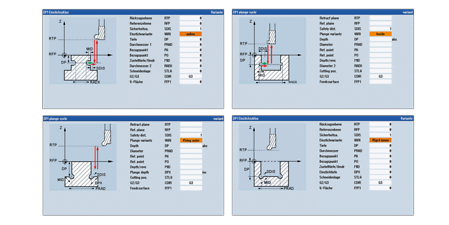

- 用长刀加工高大工件内部时,充分利用加工区

- B轴的位置变化在车削中由X轴和Y轴平衡

- B轴运动时,Z轴保持在退离位置不动

- 轻松编程

- 无碰撞地切入工件

- 加工后安全地退出工件

- 操作简单,只需三个参数,无需附加传感器

- 调节速度,避免振动

- 主轴和副主轴应用,或带Direct Drive FD工作台的铣削加工中心应用

- 无需操作人员手动干预

- 所有工件完全一致的重复精度

- 避免振动,提高特殊应用的工艺安全性。例如,使用细长钻头时或使用敏感夹具铣削工件时

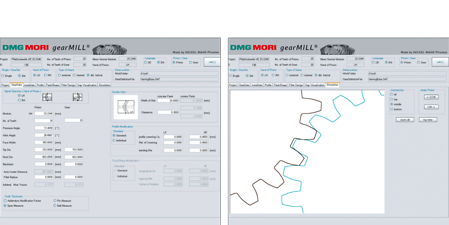

- 高生产力的完整加工

- 用标准机床和标准刀具经济地加工齿轮

- 灵活通用,适用于多种齿轮几何

- 机内质量检测

- 根据毛坯图和齿轮数据编程

- 优化工件方向,例如热处理后

- 三坐标测量设备(Klingenberg,Leitz,Zeiss)接口

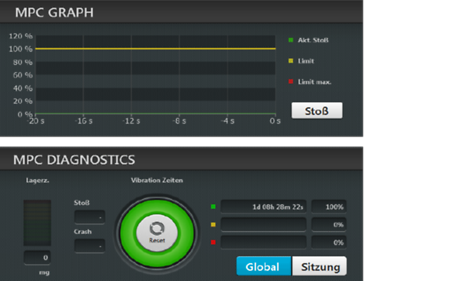

- 加工过程中的振动监测

- 碰撞时快速关机

- 即使在摆动位置,也可以手动退刀

- 新:扭矩监测

- 新:推荐用于CTX TC系列车削中心的保护套件

- 避免刀具破损

- 更高机床可用性

- 减少故障

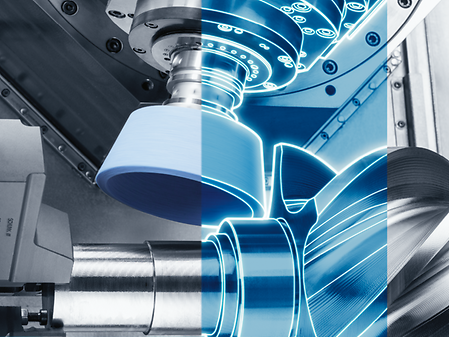

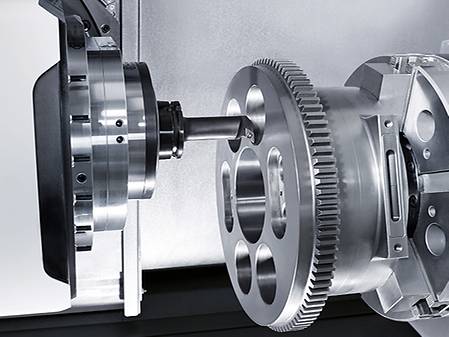

车削

- 车削、铣削和磨削一次装夹完成

- 内磨、外磨和端面磨的磨削循环以及修整循环n

- 用于启动和修整的体载声音传感器

- 完全集成测量模块,用于相对和绝对现场测量 - 与主时间并行

铣削

- 集成磨削技术,提高表面质量

- 内圆、外圆和平面磨削以及修磨循环

- 为启动和进行修磨操作的机内声音传感器

- 1,300 l冷却系统,带离心过滤器,过滤> 10 μm的颗粒物

- 选配AKZ喷嘴单元,以更好地冲洗磨削空隙

- 在车/铣复合中心上高效使用一个以上切削刃的多刀尖车刀

- 一个主刀座提供多个“姊妹刀”

- 缩短换刀时间

- 节省刀库位置

- 车削运动与附加的X轴和Y轴叠加

- 适用于车削与铣削加工

- 轻松加工偏心几何

- 进给轴在后台准确联动和同步

- 铣削椭圆形和多边形几何体

- 可加工偏心面多边形

- 简单选择合适的加工策略

- 根据 DIN 32711 和 DIN 32712 标准对轴毂连接进行简单的参数定义

- 可加工小型工件或长崩角材料。是多边形/椭圆形车削的完美补充。

- 自动识别刀具夹紧力,实现极佳的过程稳定性

- 自动润滑循环预设,每 75 小时或 20,000 换刀后

- 检测气动系统的泄漏并测量其使用量

- 无需操作人员介入,润滑省时高效

- 通过显示润滑循环和当前夹持力实现高透明性。

- 数据采集结合可选配的 Condition Analyzer,以对空气消耗和夹持力变化进行分析

- 插补车削时,刀具沿圆弧运动,同时刀具始终朝向圆心位置

- 适用于外圆和内圆加工

- 由循环控制同步和刀具路径

- 新:在 2.0 版中可实现复杂的车削轮廓(目前仅适用于 DMU 50,其他机床类型将陆续推出)

- 轻松加工密封面,其位置难以在铣削加工中接近

- 一次装夹完成工件的全部加工

- 降低刀具成本

- 测量工件上的腹板和凹槽

- 测量难以接近位置的直径

- 可手动和可伸缩,校准单元套件包括

- 适用于客户特别设计的L形测头

- 灵活通用的应用

- 机内测量

服务和培训

技术参数

了解推动我们行业发展的专业技术文章、分析资料和背景信息。

- 无限产品体验——解锁所有的机床技术数据和产品宣传手册。

- 观看专属视频,阅读技术文章,白皮书和博客文章,深入了解 DMG MORI 的产品世界。

- 个性化访问其他 DMG MORI 平台,包括 活动平台、媒体库及更多。

登录您的 DMG MORI 账号查找专属内容。

- 无限产品体验——解锁所有的机床技术数据和产品宣传手册。

- 观看专属视频,阅读技术文章,白皮书和博客文章,深入了解 DMG MORI 的产品世界。

- 个性化访问其他 DMG MORI 平台,包括 活动平台、媒体库及更多。

了解更多有关 DMG MORI 账号的信息。

登录您的 DMG MORI 账号查找专属内容。

- 无限产品体验——解锁所有的机床技术数据和产品宣传手册。

- 观看专属视频,阅读技术文章,白皮书和博客文章,深入了解 DMG MORI 的产品世界。

- 个性化访问其他 DMG MORI 平台,包括 活动平台、媒体库及更多。

了解更多有关 DMG MORI 账号的信息。

获取众多有用的数字功能和服务,所有重要数据一目了然。只需使用一个 DMG MORI 账号,即可随时随地通过任何设备使用我们的服务。

- 无限产品体验——解锁所有的机床技术数据和产品宣传手册。

- 观看专属视频,阅读技术文章,白皮书和博客文章,深入了解 DMG MORI 的产品世界。

- 个性化访问其他 DMG MORI 平台,包括 活动平台、媒体库等等。

了解更多有关 DMG MORI 账号的信息。

共有ハブやその他の機能・サービスへのアクセスをアンロックしてください。総合的な DMG MORI アカウントを使うと、いつでもどこからでも、またどのデバイスでも全サービスを使用できます。

- 無制限の製品体験 – 全ての技術機械データと製品パンフレットをアンロック。

- DMG MORI 製品の世界を深く掘り下げた独占ビデオや技術記事、ブログ記事。

- イベントプラットフォームやメディアライブラリなど、DMG MORI の他のプラットフォームへのパーソナライズされたアクセス。

DMG MORI アカウントの詳細をご覧ください。

- 无限产品体验——解锁所有的机床技术数据和产品宣传手册。

- 观看专属视频,阅读技术文章,白皮书和博客文章,深入了解 DMG MORI 的产品世界。

- 个性化访问其他 DMG MORI 平台,包括 活动平台、媒体库及更多。

了解更多有关 DMG MORI 账号的信息。

- 无限产品体验——解锁所有的机床技术数据和产品宣传手册。

- 观看专属视频,阅读技术文章,白皮书和博客文章,深入了解 DMG MORI 的产品世界。

- 个性化访问其他 DMG MORI 平台,包括 活动平台、媒体库及更多。

了解更多有关 DMG MORI 账号的信息。

- 无限产品体验——解锁所有的机床技术数据和产品宣传手册。

- 观看专属视频,阅读技术文章,白皮书和博客文章,深入了解 DMG MORI 的产品世界。

- 个性化访问其他 DMG MORI 平台,包括 活动平台、媒体库及更多。

了解更多有关 DMG MORI 账号的信息。

如需一般咨询,请填写我们的联系表格。

非常感谢您对我们的产品感兴趣。

要下载我们的PDF手册,请填写下面的表格。

如果您接受cookies的存储,在您访问期间,此表格只出现一次。