第二代NLX 2500

DMG MORI 畅销产品的重生 - 完全现代化

亮点

可对最大尺寸为 Ø 366 x 1,258 mm 的工件进行 6 面完整加工,Y 轴行程为 +/- 60 mm

- MASTER 主轴享有 36 个月质保期且无运行时间限制

- 左侧主轴:10 英寸,5,000 rpm,843 Nm,或 12 英寸,3,000 rpm,1,273 Nm,选配

- 右侧主轴(选配):从 6 英寸(转速 7,000 rpm,95 Nm)到 10 英寸(转速 5,000 rpm,最大扭矩 577 Nm)

最高铣削性能

- BMT 刀塔:转速高达 12,000 rpm,扭矩达 100 Nm,最多 20 个刀位(VDI = 12 个刀位)

- 高转速规格:转速高达 12,000 rpm,扭矩达 86 Nm

- 高扭矩规格:转速高达 6,000 rpm,扭矩达 100 Nm

GREENMODE(绿色模式) 用于降低能耗

- 能源消耗减少 16%*、润滑油消耗减少 44%、压缩空气消耗减少 12%

- 400 V 的机床可降低高达 6% 的能耗

- 环保型冷却液和雾气解决方案,可延长冷却液寿命并降低能耗

(* 此值适用于 NLX 2500 | 700)

完美契合自动化及批量生产需求

- 即插即用自动化接口和多种自动化解决方案,并支持改造升级

- 不锈钢与陶瓷涂层防护罩,确保完美排屑

- 完美的切屑、冷却液与雾气管理系统,配有 900 升 zero-sludge(零污泥)COOLANT pro 油箱且 zeroFOG 易于维护

- 采用带内置污泥和油收集系统的 zero-sludgeCOOLANT pro 油箱,延长冷却液寿命

- 采用通用型自清洁切屑输送系统,降低维护需求

应用举例

自动化系统

自动化重塑生产

提高生产力,提高质量,实现24/7生产模式。DMG MORI的解决方案可增加机床生产时间,达到更高可持续性。DMG MORI创新的自动化解决方案优化您的工艺!

GX 3 / 5 / 7 / 15 // GX 5 / 10 T - 用于一台或多台床的模块化龙门装载站系统

- 为一台机床或连接几台机床进行高生产率和灵活的工件搬运

- GX 10 T:可处理最大尺寸为Ø 200 x 150 mm、重量为10 kg的工件

- 可与各种自动周边设备(清洗、测量、打标等)组合,并可提供灵活设计的夹持器

- 由于集成到机床内控制,易于编程和设置

- 可通过DMG MORI Messenger监控负载状态

GX 3 / GX 5 / GX 7 / GX 15 / GX 5 T / GX 10 T / GX 15 T亮点

- 可操作的工件达ø 200 mm,长度达150 mm,重量达10 kg

- 结构紧凑,占地少,自带装件机

- 灵活的设计,允许组合各类自动化的辅助设备(清洗、测量、打标等)和抓手

- 集成在机床数控系统内,轻松编写程序和进行设置

- DMG MORI Messenger提供装件状态的监测信息

- 轻松扩展至两台或更多台机床

- 选配运送重量达100 kg

Robo2Go车削 - 灵活的工件搬运,适用于中小批量

- 一个应用程序统一控制所有Robo2Go变体,设置一个新工件<5分钟

- Robo2Go车削,机器人有效载荷12、25或35公斤

- 从卡盘到轴类零件存储的快速转换

- Robo2Go视觉,机器人有效载荷35公斤

- 强大的3D摄像识别功能,是多工种功能的理想选择

- 通过CELOS APP集成到机床控制操作中:不需要改变你的NC程序!

- 对话引导式软件使其具有直观的可用性

- 通过拖放预定义的程序模块来创建工艺:不需要机器人编程知识

- 设置一个新工件< 5分钟

- 从卡盘到轴类零件存储的快速转换

- 可处理ø 20 – 170毫米的轴类和ø 20 – 175毫米的盘类零件

- 负载重量为12、25和35 kg

- 工件堆放

Robo2Go 翻转装置的存储扩展能力

- 容量比标准高 300

- 工件存储的主要时间平行设置

- 在标准系统中,每个抽屉和每个抽屉内可进行多项工作

- 通过 Robo2Go 工作应用程序对所有工作进行管理

- 强大的3D摄像识别,是多任务功能的理想选择

- 原材料和成品部件按托盘进料和出料

- ø 25 – 175 mm的圆柱形盘类零件

Robo2Go MAX - 灵活的工件搬运,最高可达115公斤

- 一个应用程序统一控制所有Robo2Go变体,设置一个新的工件< 5分钟

- 最强大的版本,机器人有效载荷210公斤,工件重量115公斤

- 标准配置可搬运直径ø40至ø400毫米的工件

- 使用托盘或工件手推车快速供应和移除毛坯和成品零件

- 可自由进入控制和工具库

- 最强版本,有效载荷210 kg,工件重量115 kg

- 标准配置可搬运直径40到ø 400 mm的工件

- 通过托盘或工件推车,快速输入和输出加工好的工件

- 可自由操作控制系统和刀库

- 最强版本,有效载荷210 kg,工件重量115 kg

- 标准配置可搬运直径40到ø 400 mm的工件

- 通过托盘或工件推车,快速输入和输出加工好的工件

车间整体自动化

- 协同自动化解决方案,自由式布局设计

- 可全向移动,空间需求最小(车削半径 0m)

- 在此基础上执行其他任务,例如,B 轴刀具搬运、切屑处理等

- 使用 1,200 x 800 mm 欧标托盘进行材料运输

- 运输重量最大达 2,000 kg

- 基于 Sick 和 Siemens 安全技术

- 物料托盘自主输送

- 输送不同载荷的载具

- 集成至 DMG MORI 自动系统以实现工件搬运——成品与毛坯件托盘的交换

- 集成至现有生产工艺

- 以后可扩展和扩容

- 切屑容器自主输送

- 来自主计算机的自动输送指令

- 扩展的机床自主性

- 物料和切屑可合并输送

- 标准中的刀具识别

- 机床与刀具存储系统之间刀具的自主输送与交换

- 最大刀具尺寸 ø 280 / 400 毫米

- 最大刀具重量 30 千克

- 输送重量 720 千克(24× 30 千克)

- 最大刀具数量:24 件

高度灵活、协作性强的自动化系统,可处理重达 10 公斤的工件

- 可自由移动的工件处理装置,包括机器人和手推车上的存储区

- 工件重达 10 千克,或 5 × 2 千克(带双手爪)

- 基础设施不变

- 无需安全围栏

- 占地面积 600 × 900 毫米

- 协作机器人,设置时间小于 5 分钟*

- 无需机器人知识的直接示教

- 通过以太网轻松连接

- 可选择两种类型的料库

- 最多可存储 64 个工件

- 吹气清洁装置

- 二次定位台

*当选择了可选的标签位置校正功能或机器/工件设置已完成时。

适用于NTX系列的完美机器人自动化方案

- 机器人进行装卸

- NTX 500

- 机器人最大传送重量:7 千克 (每只手的最大工件重量:2 千克)

- 最大工件直径 Φ70 毫米

- 最大工件长度: 65 毫米

- NTX 1000

- 机器人最大搬运重量:12 千克(发那科),10 千克(库卡) (参考每只手的最大工件重量:2 千克)

- 最大工件直径 Φ70 mm

- 最大工件长度:100 毫米

灵活的模块化机器人系统,适用的机床数≥1台机数

- 模块化概念设计的标准化辅机设备,如清洗、测量或打标

- 得益于模块化和标准化的辅机设备和机器人程序,安装时间缩短80%

- 灵活适应系统变化,包括安装后的变化

- 通过MATRIS控制系统简单易行,无需编程

- 日产50至200件,灵活生产的理想选择

- 占地少的托盘运送系统,多达40盘位

- 400 × 400 mm的托盘规格

- 运送重量达150 kg(工件和托盘)

- 含辅助操作,例如去毛刺或打标

- 可配CMX 50 U, CMX 70 U, DMU 50, DMU 65 monoBLOCK, CMX 600 V, CMX 800 V, CMX 1100 V

灵活的布局设计确保了工件自动化的灵活性最大化

- 自由布局设计的模块化概念

- 无需导轨或轨道的无人驾驶运输系统

- 协作性:人和机床在一个系统中

- 视觉传感器使机器人手臂定位精度优于±1毫米

- 最大工件尺寸为Ø 150 × 120 mm,重量为10 kg

- 紧凑型设计 (700 × 1,035 mm)

- 激光传感器

- 卓越的操作性能和稳定性,包括在不平整的地面上

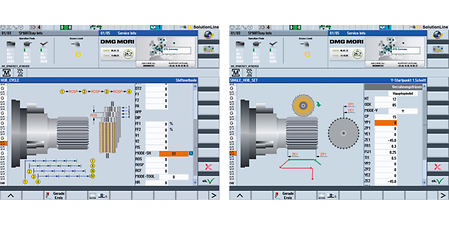

数控系统和软件

体验数字化转型(DX)的高速度

降低能耗,变革操作方式、发现新商机、提高工作效率和可持续性,并增强竞争优势。

- 特别适用于多通道机床分析生产工时的应用以及作为优化周期时间的基础

- 局部缩放详细地查看周期时间优化的任何细节

- 多达三个通道的直方图

- 提供图形化显示周期时间优化的基础

- 保存/加载记录的数据,以比较各个优化步骤

- 自动优化主轴和副主轴的伺服驱动参数

- 减少装夹设置时间

- 优化加工效果

- 减少装夹设置时间

- 自动确定参数,与机床操作人员的经验无关

- 设置被保存在 NC 程序中,从而保证质量统一性

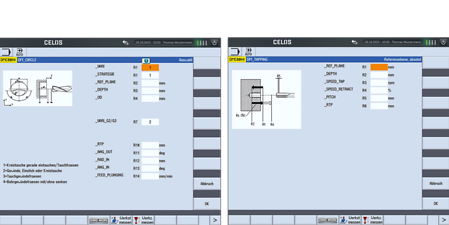

- 轻松加工非圆形工件

- 车削多边形/椭圆的直观用户界面

- 简单的精车加工要求的几何

- 根据几何参数做精车成为可能

- 结合主轴和副主轴进行加工

- 进给轴的摆动运动导致气切削,从而有效减少切屑尺寸

- 用于内外径外纵向车削、端面车削、钻孔和切槽*。

- 集成安全功能检查参数输入的合理性

* 对于倾斜表面,由于进给一次只能在一个轴上摆动,因此会产生阶梯模式。

- 切屑长度实际上可由周期决定,与材料无关

- 由于避免了切屑球的产生,因此不再需要中断工序

- 人机界面易于设置,操作安全性高

- 通过刀片长度方向上力的优化传导实现更高的稳定性

- 按下按钮,刀具在 Y 方向上进给切断部件

- 与标准循环 CYCLE92 (Part off cycle) 适配,从而使操作人员可以像通常一样编程 (ShopTurn and DIN / ISO)

- 生产率最高可达三倍(三倍进给),同时优化切屑控制

- 刀具稳定性更佳,从而使得噪声水平更低,表面质量更佳

- 减小切断宽度,从而降低物料损耗

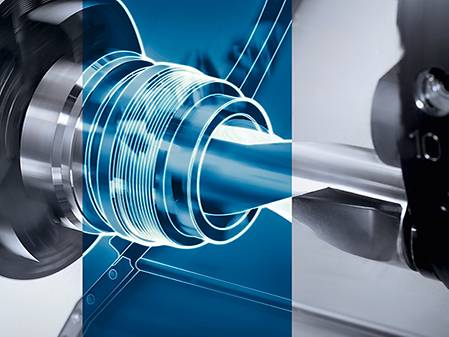

- 新:定点螺纹加工 - 定向的螺纹加工

- 自定义齿廓、螺距和齿形

- 加工大型传动螺纹,其难以用套丝方式加工

- 在机床上轻松编写梯形、锯齿和圆顶螺纹加工程序

- 任何齿廓几何的螺旋推进器

- 轻松加工带十字孔的滚珠丝杠螺母

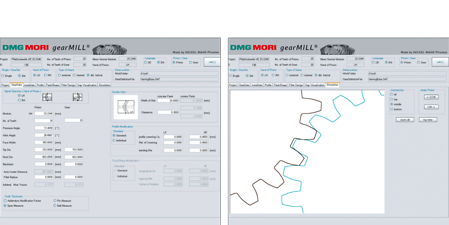

亮点

- 凭借高解析度的轮廓分割,生产带底切的轮廓。

- 使用标准刀具和刀柄进行左侧和右侧齿面加工

- 铬镍合金表面质量可达 Ra 0.3

- 操作简单,只需三个参数,无需附加传感器

- 调节速度,避免振动

- 主轴和副主轴应用,或带Direct Drive FD工作台的铣削加工中心应用

- 无需操作人员手动干预

- 所有工件完全一致的重复精度

- 避免振动,提高特殊应用的工艺安全性。例如,使用细长钻头时或使用敏感夹具铣削工件时

- 高生产力的完整加工

- 用标准机床和标准刀具经济地加工齿轮

- 灵活通用,适用于多种齿轮几何

- 机内质量检测

- 根据毛坯图和齿轮数据编程

- 优化工件方向,例如热处理后

- 三坐标测量设备(Klingenberg,Leitz,Zeiss)接口

- 按下相应按键,X轴和Y轴运动到外圆加工的正方向终点位置

- 适用于为设置准备加工区或用作急救功能

- 简化多通道机床的设置操作

- 外圆加工过程中可快速响应,起到急救作用

- 避免刀具破损或刀具过载导致的故障

- 无传感器地自动确定负载极限

- 适用于车削、铣削和钻削加工(直径达3 mm)

- 新:CELOS边栏的用户界面

- 新:高效算法,首件后有效监测

- 防护套件:MPC车削中心的完美补充。价格优惠(约40%)

- 在程序中保存每把刀具和每个切削刃的监测范围

- 车削运动与附加的X轴和Y轴叠加

- 适用于车削与铣削加工

- 轻松加工偏心几何

- 进给轴在后台准确联动和同步

- 安全工艺解决方案和高效使用重要加工步骤解决方案

- 应用:刀柄清洁、刀具数据监测、安全退刀运动、攻丝、深孔钻、外螺纹和螺栓铣削、内螺纹和圆弧铣削、反向锪孔循环

- 针对车削、深钻孔、型腔铣的12种加工策略

- 根据各个应用,优化运行时间

- 程序中断后,安全退刀

- 刀具数据监测

服务和培训

全面的贴心服务和生产培训

DMG MORI提供全面的服务和实践培训,以充分发挥机床的工作性能,压缩停机时间。DMG MORI还为您提供全面的维护方案、原厂备件和量身定制的培训课程,有效提升您的生产和员工能力。

技术参数

了解推动我们行业发展的专业技术文章、分析资料和背景信息。

- 无限产品体验——解锁所有的机床技术数据和产品宣传手册。

- 观看专属视频,阅读技术文章,白皮书和博客文章,深入了解 DMG MORI 的产品世界。

- 个性化访问其他 DMG MORI 平台,包括 活动平台、媒体库及更多。

登录您的 DMG MORI 账号查找专属内容。

- 无限产品体验——解锁所有的机床技术数据和产品宣传手册。

- 观看专属视频,阅读技术文章,白皮书和博客文章,深入了解 DMG MORI 的产品世界。

- 个性化访问其他 DMG MORI 平台,包括 活动平台、媒体库及更多。

了解更多有关 DMG MORI 账号的信息。

登录您的 DMG MORI 账号查找专属内容。

- 无限产品体验——解锁所有的机床技术数据和产品宣传手册。

- 观看专属视频,阅读技术文章,白皮书和博客文章,深入了解 DMG MORI 的产品世界。

- 个性化访问其他 DMG MORI 平台,包括 活动平台、媒体库及更多。

了解更多有关 DMG MORI 账号的信息。

获取众多有用的数字功能和服务,所有重要数据一目了然。只需使用一个 DMG MORI 账号,即可随时随地通过任何设备使用我们的服务。

- 无限产品体验——解锁所有的机床技术数据和产品宣传手册。

- 观看专属视频,阅读技术文章,白皮书和博客文章,深入了解 DMG MORI 的产品世界。

- 个性化访问其他 DMG MORI 平台,包括 活动平台、媒体库等等。

了解更多有关 DMG MORI 账号的信息。

共有ハブやその他の機能・サービスへのアクセスをアンロックしてください。総合的な DMG MORI アカウントを使うと、いつでもどこからでも、またどのデバイスでも全サービスを使用できます。

- 無制限の製品体験 – 全ての技術機械データと製品パンフレットをアンロック。

- DMG MORI 製品の世界を深く掘り下げた独占ビデオや技術記事、ブログ記事。

- イベントプラットフォームやメディアライブラリなど、DMG MORI の他のプラットフォームへのパーソナライズされたアクセス。

DMG MORI アカウントの詳細をご覧ください。

- 无限产品体验——解锁所有的机床技术数据和产品宣传手册。

- 观看专属视频,阅读技术文章,白皮书和博客文章,深入了解 DMG MORI 的产品世界。

- 个性化访问其他 DMG MORI 平台,包括 活动平台、媒体库及更多。

了解更多有关 DMG MORI 账号的信息。

- 无限产品体验——解锁所有的机床技术数据和产品宣传手册。

- 观看专属视频,阅读技术文章,白皮书和博客文章,深入了解 DMG MORI 的产品世界。

- 个性化访问其他 DMG MORI 平台,包括 活动平台、媒体库及更多。

了解更多有关 DMG MORI 账号的信息。

- 无限产品体验——解锁所有的机床技术数据和产品宣传手册。

- 观看专属视频,阅读技术文章,白皮书和博客文章,深入了解 DMG MORI 的产品世界。

- 个性化访问其他 DMG MORI 平台,包括 活动平台、媒体库及更多。

了解更多有关 DMG MORI 账号的信息。

如需一般咨询,请填写我们的联系表格。

非常感谢您对我们的产品感兴趣。

要下载我们的PDF手册,请填写下面的表格。

如果您接受cookies的存储,在您访问期间,此表格只出现一次。