ULTRASONIC 200 Gantry

5-axis ULTRASONIC machining in XXL

X 轴的最大行程

157 in.

4,000 mm

Y 轴的最大行程

79 in.

2,000 mm

Z 轴的最大行程

47 in.

1,200 mm

最大工件长度

169 in.

4,300 mm

最大工件宽度

79 in.

2,000 mm

最大工件高度

49 in.

1,250 mm

工件最大重量

44,092 lbs.

20,000 kg

可选配的数控系统及软件

SIEMENS

亮点

ULTRASONIC technology integration - reduced process forces for higher productivity

- Technology integration via HSK-A63 / HSK-A100 interface for ultrasonic superimposition of the tool rotation with amplitudes up to 15 µm

- Process forces reduced by up to 50% through ULTRASONIC enable, depending on requirements: higher feed rates, improved surface quality up to Ra <0.1 µm, longer tool life

- Specific coolant treatment systems with centrifuges, optimized for the ULTRASONIC processing of Advanced Materials

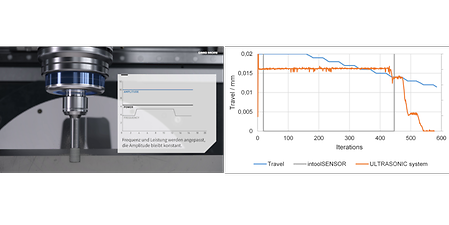

ULTRASONIC 3rd Generation - Optimal process control through intelligent controls

- Constant amplitude in the process to ensure reproducibility

- Automatic detection of the working frequency, significantly improved hardware for signal acquisition

- Frequency tracking and simultaneous power control in real time for optimal process stability

- Ensuring the ULTRASONIC advantages even with non-optimal tools

- Fully compatible with 2nd generation ULTRASONIC actuator

5轴加工

- 45°摆动铣头的摆动范围为90°和回转范围为+/- 300°

- compactMASTER主轴,转速20,000 rpm

- 90°摆动铣头的摆动范围为+/- 120°和回转范围为+/- 300°

- compactMASTER主轴,转速20,000 rpm,最高转速30,000 rpm

应用举例

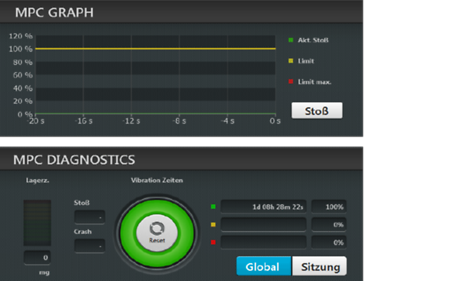

数控系统和软件

CELOS

将DMG MORI机床和车间数字化:

- CELOS机床:基于APP应用程序的用户界面,提供有关生产的全面信息

CELOS生产:27款CELOS APP应用程序,有效准备和处理任务单

- 数字化工厂:连续的数字化工作流程,从生产计划到生产和服务